Consolidation of the Chinese Export Lacquer Desk

Photo taken by Jim Schneck

Accession #: 1962.222 A-C

Object: Lacquer Desk

Object Date: 1820-1840

Maker/Artist: Unknown maker, China, acquired in 1962

Materials: Lacquer, wood (Glyptostrobus pensilis, or Chinese Swamp Cyprus), brass, ivory, glass mirror, fabric

Dimensions: Overall - H 141.5 cm W 68.5 cm D 60.0 cm

Sub A - H 67.8 cm W 68.5 cm D 60.0 cm Sub B - H 12.9 cm W 68.5 cm D 32.5 cm Sub C - H 74.0 cm W 72.0 cm D 26.5 cm

Creation Place: Canton, China

Permanent Location: China Trade Room, Winterthur Museum

Examined by: Amaris Sturm and Ersang Ma. WUDPAC, Class of 2018

Consulted with: Stephanie Auffret, Josh Lane, Greg Landrey, Susan Buck, Peggy Olley

Treated by: Yang Xu, 2019 Report Modified by Yang Xu

Report Date: 20 May 2019

Lacquer Construction

The Cross-section analysis conducted by Ersang Ma and Amaris Sturm in 2015 revealed the architecture of the lacquer surface. The thick ground layers are composed of one coarse ground layer on the bottom and one finer ground layer on top, with a paper applied in between the two layers. Visible under ultraviolet light, there are two layers of lacquer. In the samples with gilt decoration, the thin layer of bole to which gold leaf or powder is applied above the lacquer layers. An additional layer of varnish has been applied to the surface, which fluoresces a bright white color. According to recent material analysis conducted by Winterthur Museum on 22 objects of Chinese export lacquer from the collections of Winterthur Museum, Peabody Essex Museum (PEM) and Philadelphia Museum of Art (PMA), the two black lacquer layers were identified to be laccol and urushi from the bottom to top. (Matsen, Petisca, Auffret 2017)

Before treatment, photograph by Jim Schneck

Condition

There is cracking occurring throughout the lacquered surface. Extensive cracking and tenting of the underside of the stand (A) has occurred with active loss of the surface. There are small losses to the lacquer on the legs of the stand, likely from use, abrasion, and physical forces. There is loss to the skirt of the table, exposing ground and previous restorations.

Rationale for treatment

The goal of treatment is to stabilize the actively cracking, tenting, and lifting lacquer surface, as well as to clean the desk overall before returning the object to display in the China Trade Room. Although aesthetic improvement is not imperative in treatment, visually distracting losses and failed past restoration should be visually integrated (Auffret 2015, Lane 2015).

treatment

Dusting

• Surface clean with soft bristle brushes and vacuum, avoid areas that are too fragile to clean before consolidation.

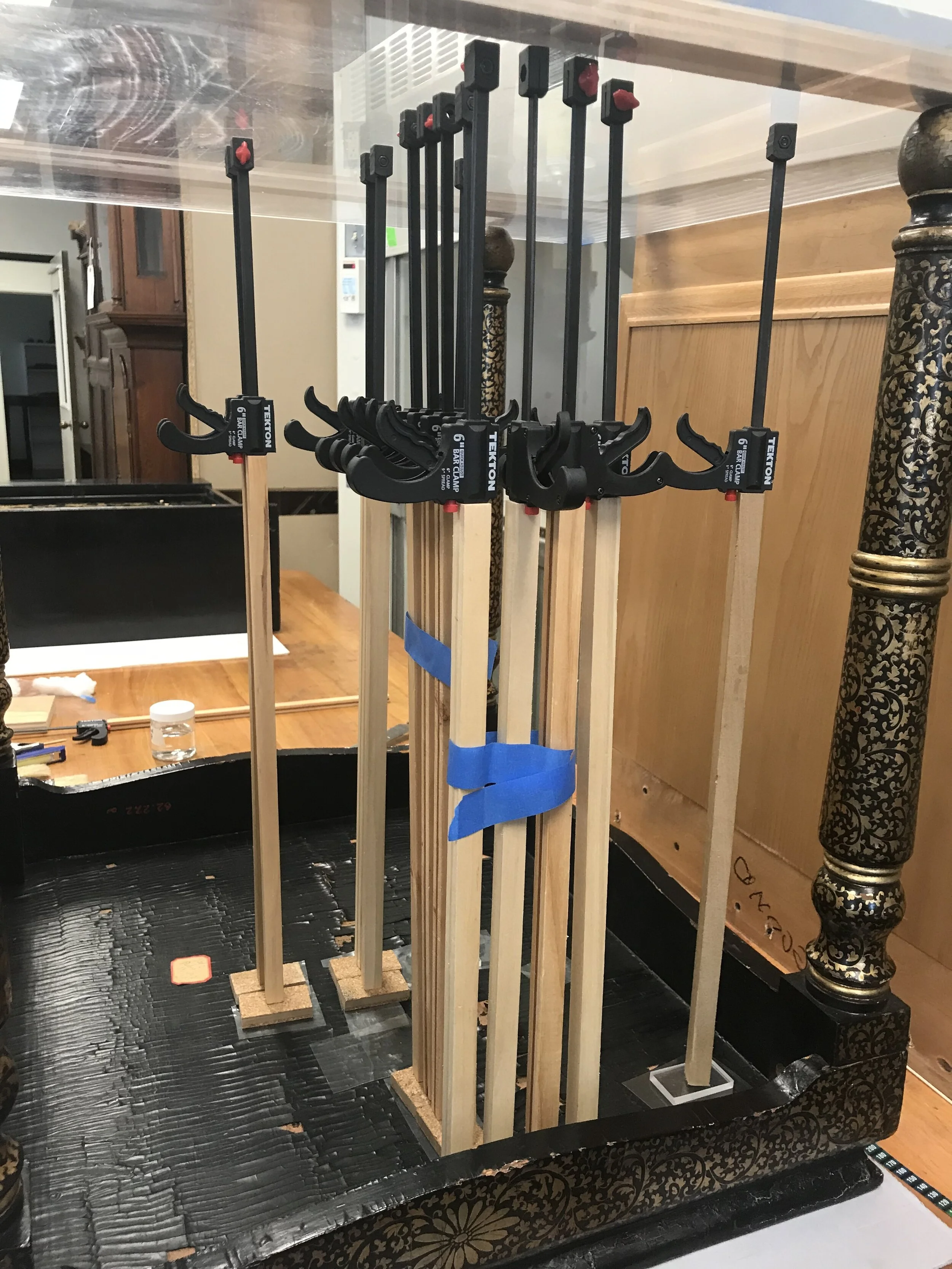

Consolidation for flaking/lifting lacquer

Lacquer is relatively stable polymer after it sets. However, degraded lacquer, especially caused by light damage, can be washed off with polar solvent, which may affect the choice of consolidants. Additionally, the lacquer and ground layers may swell while introducing moisture into the layers, compromising the structure. Another concern is the brittle flaking/lifting lacquer may not be flexible enough to be flatten and reattached to the wood substrate. Heat may be introduced to reduce the brittleness and increase the flexibility. Therefore, solubility test and consolidant test is necessary.

• Solubility test with water, ethanol, and acetone.

The lacquer film is insensitive to water and ethanol.

• Consolidation with hide glue and Lascaux 4176 Conservation Medium

- Hide glue for the severely flaking areas, where provides larger window for hide glue.

- Injected 1:1 ethanol: deionized water underneath the crack to activate the ground layer, encouraging wetting and penetration of the adhesive. Areas with raised cracks were lightly warmed with tacking iron (radiation heat) to reduce the brittleness of the lacquer.

- Inject hide glue under the crack.

- Clamp the consolidated area using silicone release mylar as a barrier layer and a warm cork pad on top to delay the glue curing time while adjusting the clamp to position.

- Check the area after 15 minutes for excess glue on the surface. Remove the excess glue and reclamp the area.

- Waited for at least 24 hours to dry

- Lascaux 4176 conservation medium for cracks and lifting, where the hide glue in high viscosity couldn’t flow into.

- Injected the medium into the contacting area.

- Waited for the adhesive to dry and relaxed the brittle lacquer flakes. Localized humidification (jars with damp cotton) was used for the stiff lacquer flakes.

- Areas with raised cracks were lightly warmed with tacking iron (radiation heat) to reduce the brittleness of the lacquer.

- Gently reactivated and flattened the surface with tacking iron (setting temperature 50°C) after the consolidant was dry, with silicon released mylar as barrier.

- Clamp the consolidated area using silicone release mylar as a barrier layer and a warm cork pad on top.

- Check the pressure of the clamps. Waited for half day.

After Consolidation

Aesthetic Enhancement

• Remove degraded old restorations that are visually distracting.

• Fill losses to wood and lacquer with dry pigment (bone black) in 8% PVOH binding. Applied the paste into the loss and used Shimbari clamps to flattened it. After it dried, burnished it. (Low efficiency)

• Due to the low efficiency of the PVOH fills, paper fill was used for this case. Laminated Japanese tissue paper with western paper to build up the thickness of lacquer and match the surface texture. Painted the laminated paper with acrylic paint to match the color. Cut the paper fill into the right shape and filled in the loss, Lascaux HV 498 as adhesive.