Conservation of the wagen wheel chair

Before treatment photography by Jim Schneck

Accession #: 13[1]

Object: Wagon Wheel Chair

Object Date: 1931

Maker/Artist: Wharton Esherick

Materials: Shagbark Hickory (Carya ovata), cowhide leather (likely a cowhide)

Dimensions: Chair - 40” L x 23.5” W x 24” D

Leather, back – 0.5” W (thickness: 0.08”)

Leather, seat – 3-4.5” W (thickness: 0.19”)

Inscriptions: Signature on the lower back of the left leg “W.E 1931”

Creation Place: Chester County, Pennsylvania

Owner: Wharton Esherick Museum

Permanent Location: Studio building, ground floor, East wall

Reason for Examination: WUDPAC Wooden Artifacts Block Documentation Project and treatment

Examined by: Katerina Acuna and Yungjin Shin. Graduate Fellow at the Winterthur/University of Delaware Program in Art Conservation, Class of 2021

Treated by: Yang Xu, Graduate Fellow at the Winterthur/University of Delaware Program in Art Conservation, Class of 2020

Report Date: 15 May 2019

[1] Accession number yet to be assigned by the Wharton Esherick Museum. “13” Is the lot number associated with this item in the division of the Esherick estate and will be used here as an identifier.

condition

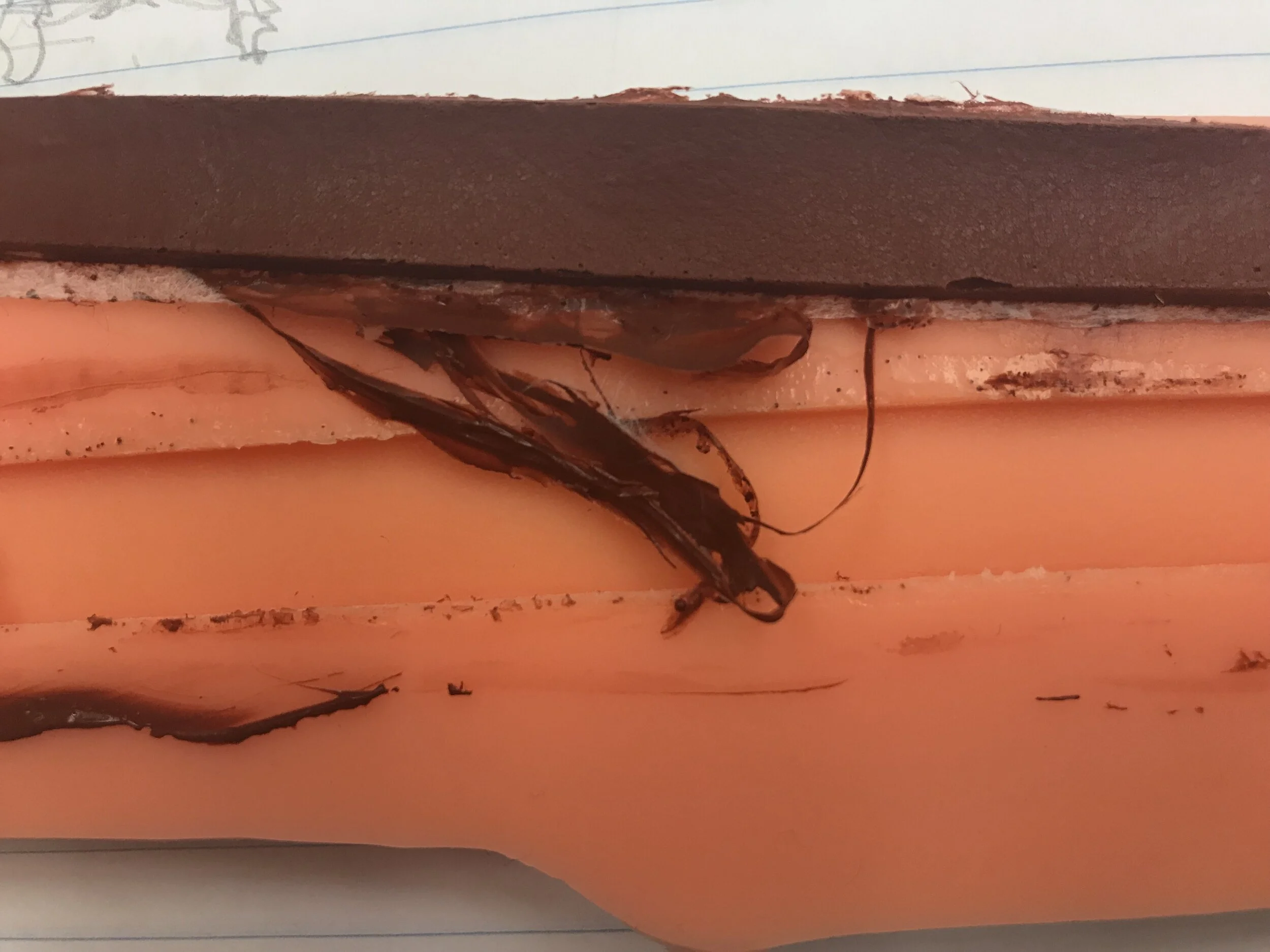

The laced leather seat and back suffer from a variety of condition issues. The leather strapping on the seat is of a broader width and appears to be in better condition than the seat back. It may have been replaced in past years by the artist’s assistant, Horace Hartshaw, but if so the restoration was never formally recorded. The nails securing the thick leather straps to the frame of the seat are discolored and encrusted with a buildup of hardened coating. The leather straps are also darkened around the iron nails, caused by the oxidation of the metal and exacerbated by the application of oil coatings (Dignard and Mason 2018). The leather strapping on the seat back shows major losses along the top portion as a result of rodent damage. During Hurricane Sandy the Wharton Esherick Museum lost power. A flying squirrel was able to enter the collection and caused the initial damage to the straps. In subsequent years, damage to the top portion of the leather seat back was exacerbated by further rodent activity.

The weaving pattern has been severely compromised. The leather straps are also brittle and mottled with a white residue that may be the result of mold, accumulated salt crystals, or spew arising from treatment of the leather with oily dressings. The straps show some uneven discoloration, but this may be a result of the material’s previous use for harnessing, since those areas appear irregularly bound to the chair. The leather also shows discoloration in areas where the straps overlap; the exposed straps are darker in color than the obscured straps. This is most likely caused by light damage. The leather straps have fused together in the highly discolored areas at the base of the seat back.

The leather is stiff and cracked, due to previous treatment with oil and uncontrolled environmental conditions. The dressing damaged the leather as the oil content oxidized and deteriorated the skin structure, causing the material to grow stiff and discolored (McCrady and Raphael 1993). In addition, the seat straps are slightly depressed, which may have been caused by past use.

Rationale for treatment

The purpose of the treatment is to treat and stabilize the damaged leather straps, so that the chair can be safely displayed in the museum without visually distracting visitors. The treatment will also increase the item’s stability in long-term display and preserve its original aesthetic.

Treatment

1. Dry cleaning with cosmetic sponge

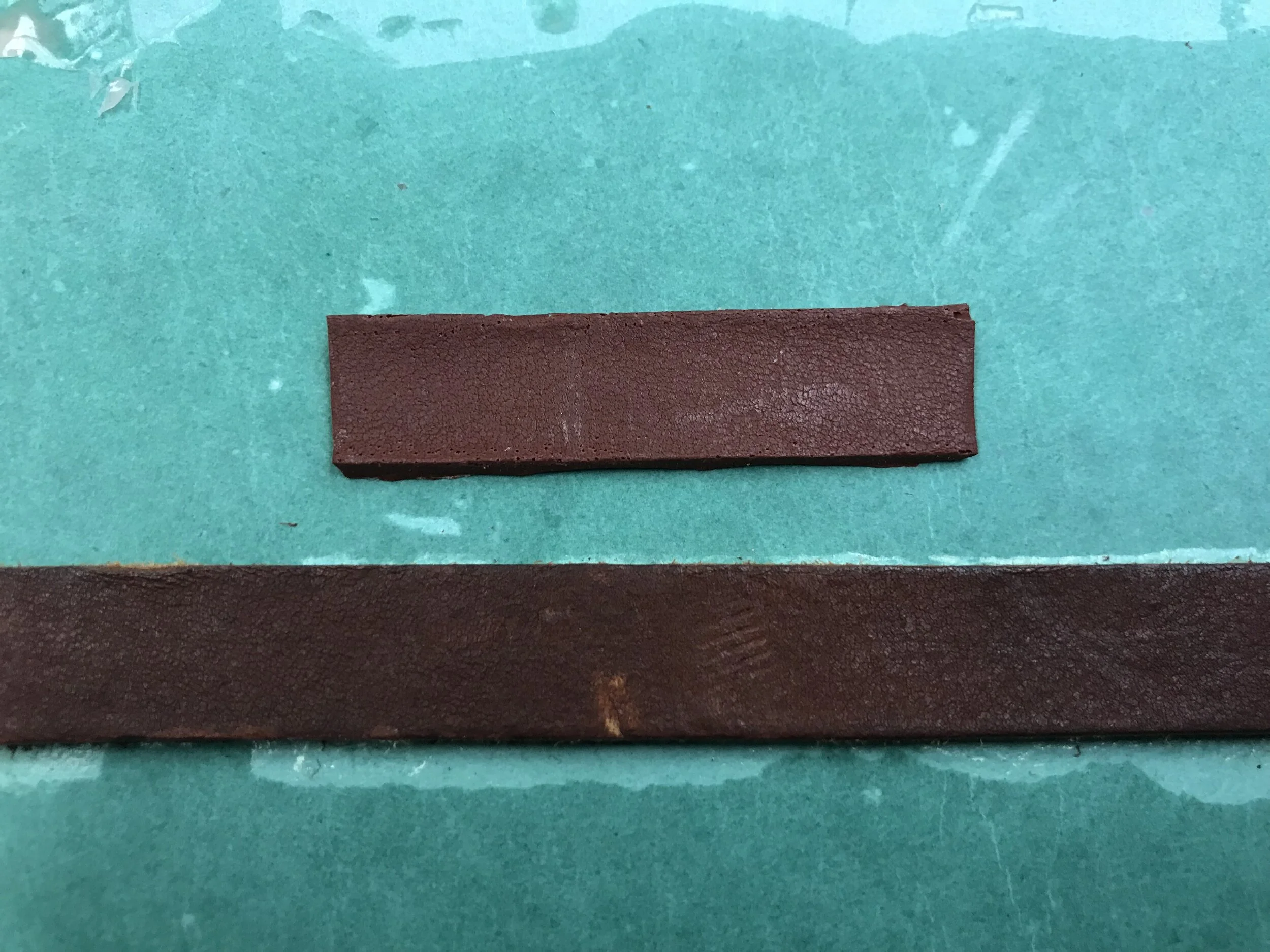

Artificial leather for mending and stabilization

2. Took silicon mold from the original leather strip.

3. Cast acrylic films with:

1 part Golden Artist Colors (GAC) Specialty Acrylic Polymer 500 additive

1 part Golden Heavy Gel Medium (matte or semi-gloss)

2 parts Golden Heavy Body Paint (color match before casting)

4. Brushed the materials above into the mold in different thickness and waited till set

5. Laminated the film (with leather texture) with ultrasuede as backing, Lascaux HV 498 as adhesive, to make artificial leather for mending.

Mending and Stabilization

6. Traced the shape of the broken edge and cut it into the shape

7. Toned Japanese tissue paper (Tengujo 12g) as backing and lining, rejoined the original leather strip with the new artificial one. Lascaux HV 360 as adhesive.

8. Toned Japanese tissue paper (Tengujo 12g) to cover the seam of the joint. Lascaux HV 360 as adhesive.

Consolidation of the original leather material

9. Consolidated the leather with 1% Klucel G in isopropanol. In severely weathered area, applied 2 to 3 times.

Surface treatment for the artificial leather

10. Used paste wax and black pigments to burnish the artificial leather. Matched the color, texture and gloss of the surface.